- Solutions

- Smart Manufacturing

- Industries

- KevSecure® Pharma Cloud for 300 Products

- KevSecure® for Pharma API

- Online Print & Inspect Systems for Cartons

- Online Print & Inspect Systems for Bottles

- Online Print & Inspect Systems for Labels

- Tamper Evident Online Print & Inspect Systems for Cartons

- Offline Print & Inspect Systems for Flat Cartons

- Offline Print & Inspect Systems for Folded Cartons

- Insights

- About

- Support

- Contact

Level 1 Solutions

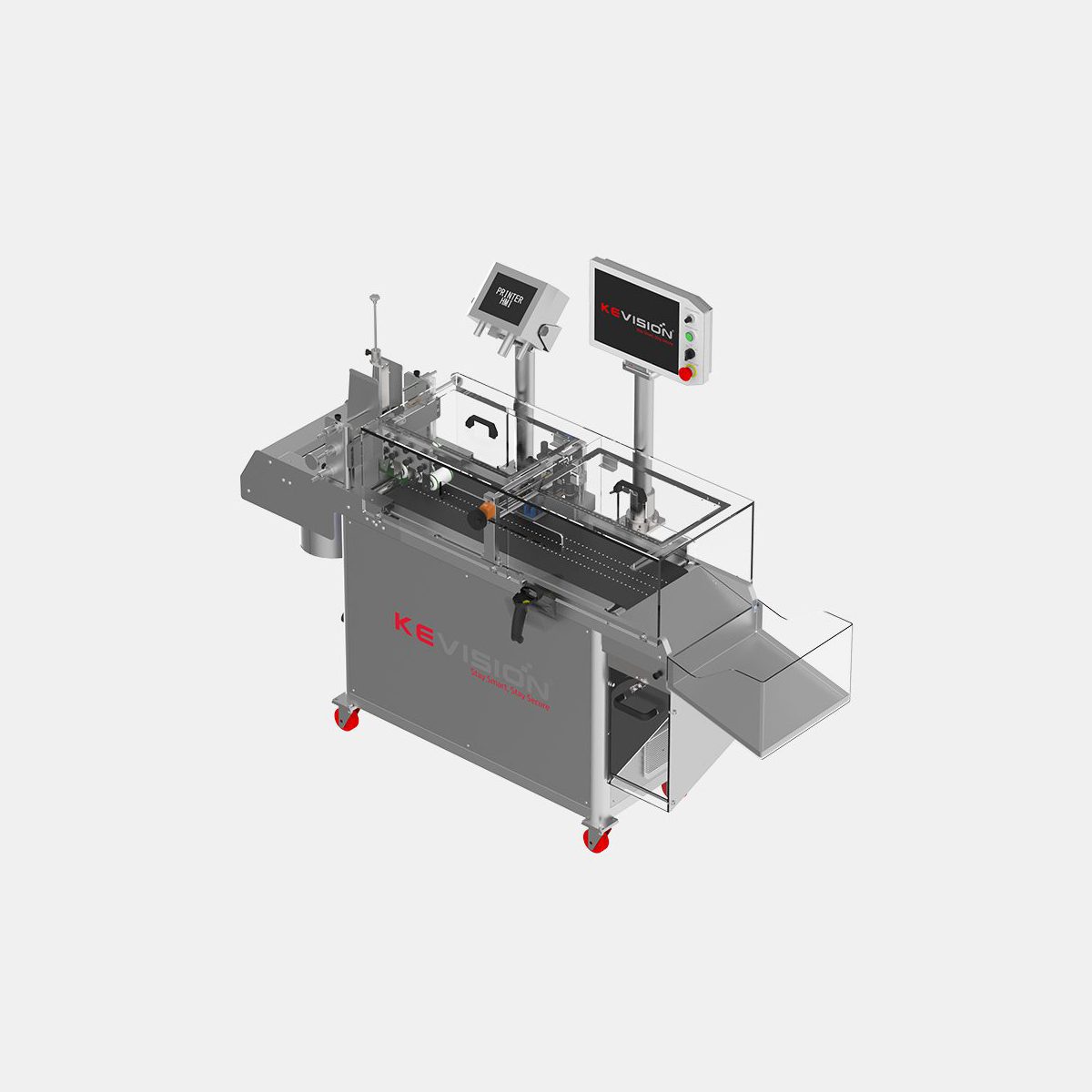

Offline Print & Inspect Systems for Flat Cartons

Our Offline Print & Inspect Systems for Flat Cartons offer a robust solution designed to streamline the pharmaceutical manufacturing process. This Level One solution combines high-performance printing, precise inspection, and efficient handling of flat cartons, ensuring optimal quality control and compliance.

Special Features

Our system features a stacker feeder that is suitable for loading unfolded cartons of different sizes. This flexibility allows for seamless integration with your production line, accommodating a wide range of carton dimensions.

Our system incorporates a specialized infeed conveyor that ensures efficient separation and dispensing of cartons onto the main conveyor. This promotes smooth and continuous carton flow, reducing downtime and improving productivity.

With a common mechanical mounting for the camera and print head, our system offers easy adjustment and alignment. This simplifies the setup process, saving time and effort while ensuring accurate printing and inspection results.

Our system utilizes a pneumatic-based rejection mechanism that swiftly identifies and eliminates cartons with errors or anomalies. An optional rejection verification feature provides an added layer of assurance, enhancing overall quality control.

Special Features

Streamline your operations with our system's single software control, which seamlessly manages the conveyor, camera inspection system, and rejection mechanism. This centralized control simplifies operation and reduces the risk of errors.

Our system includes a machine STOP feature that enables consecutive detection of incorrect barcodes. This proactive approach ensures that any deviations or discrepancies are promptly identified, maintaining the integrity of the packaging process.

Our system is designed to meet cGMP (current Good Manufacturing Practices) standards, ensuring compliance with regulatory requirements. The machine design prioritizes hygiene, cleanliness, and adherence to industry best practices.

Partner with Kevision

Experience the efficiency and reliability of our Offline Print & Inspect Systems for Flat Cartons. With features such as stacker feeding, specialized infeed conveyors, convenient mechanical mounting, and comprehensive software control, this solution offers seamless integration and optimal quality control for your pharmaceutical packaging needs.